Biosciences Partnership Building

The Biosciences Partnership Building (BSPB) is located on the Phoenix Biomedical Campus. It is a 10-story academic lab building and an addition to a medical school, also by CO Architects, the Health Sciences Education Building (HSEB). BPSB was my first professional project after graduating with my architecture degree. It offered the opportunity to understand and participate in the design process for a large, high-tech building on a contractor design-assist schedule. I was also able to apply the design computation skills I had developed in school to lead the process of facade panelization.

Work completed at CO Architects. Photos by Bill Timmerman.

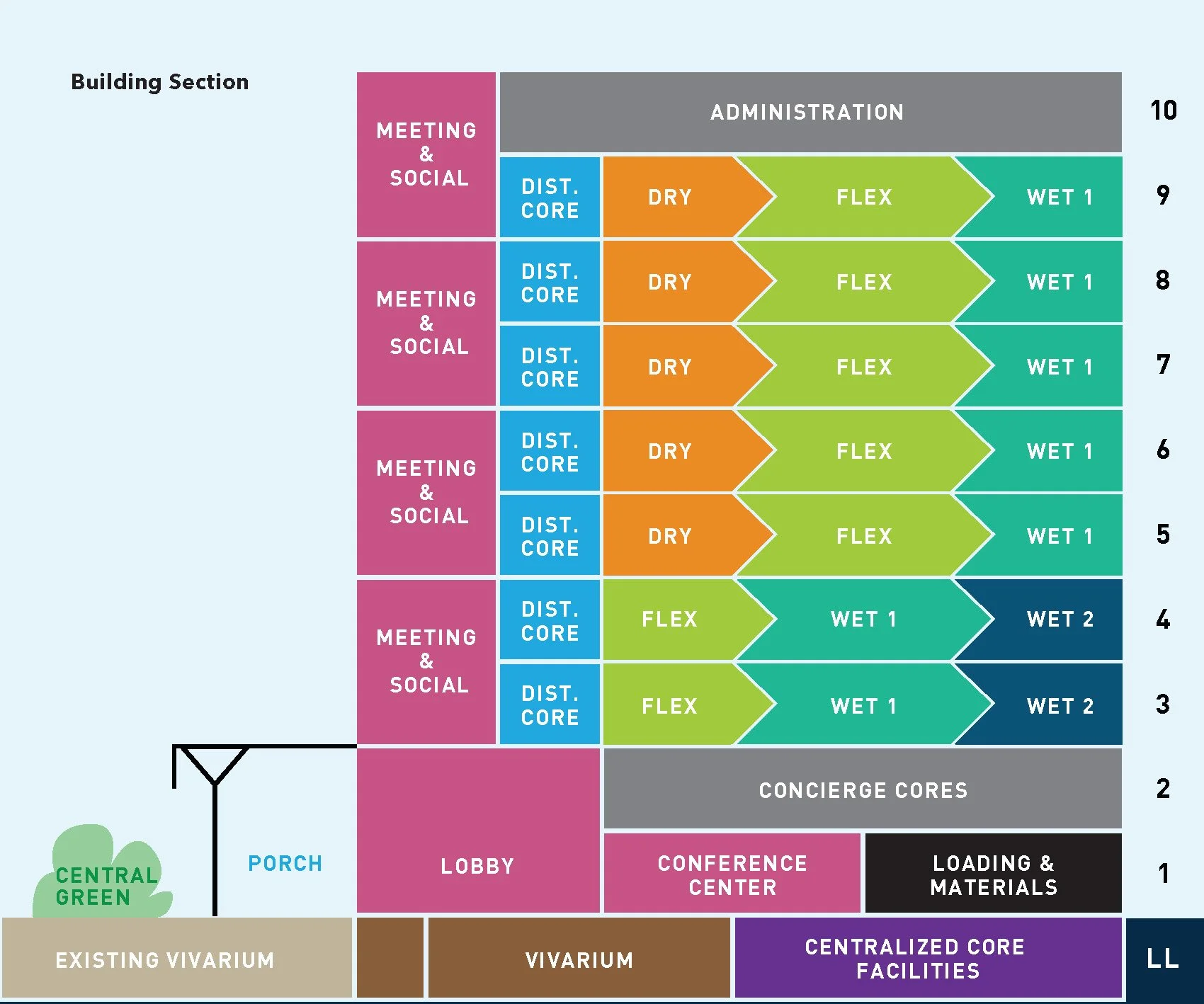

Conceptual Stacking Diagram

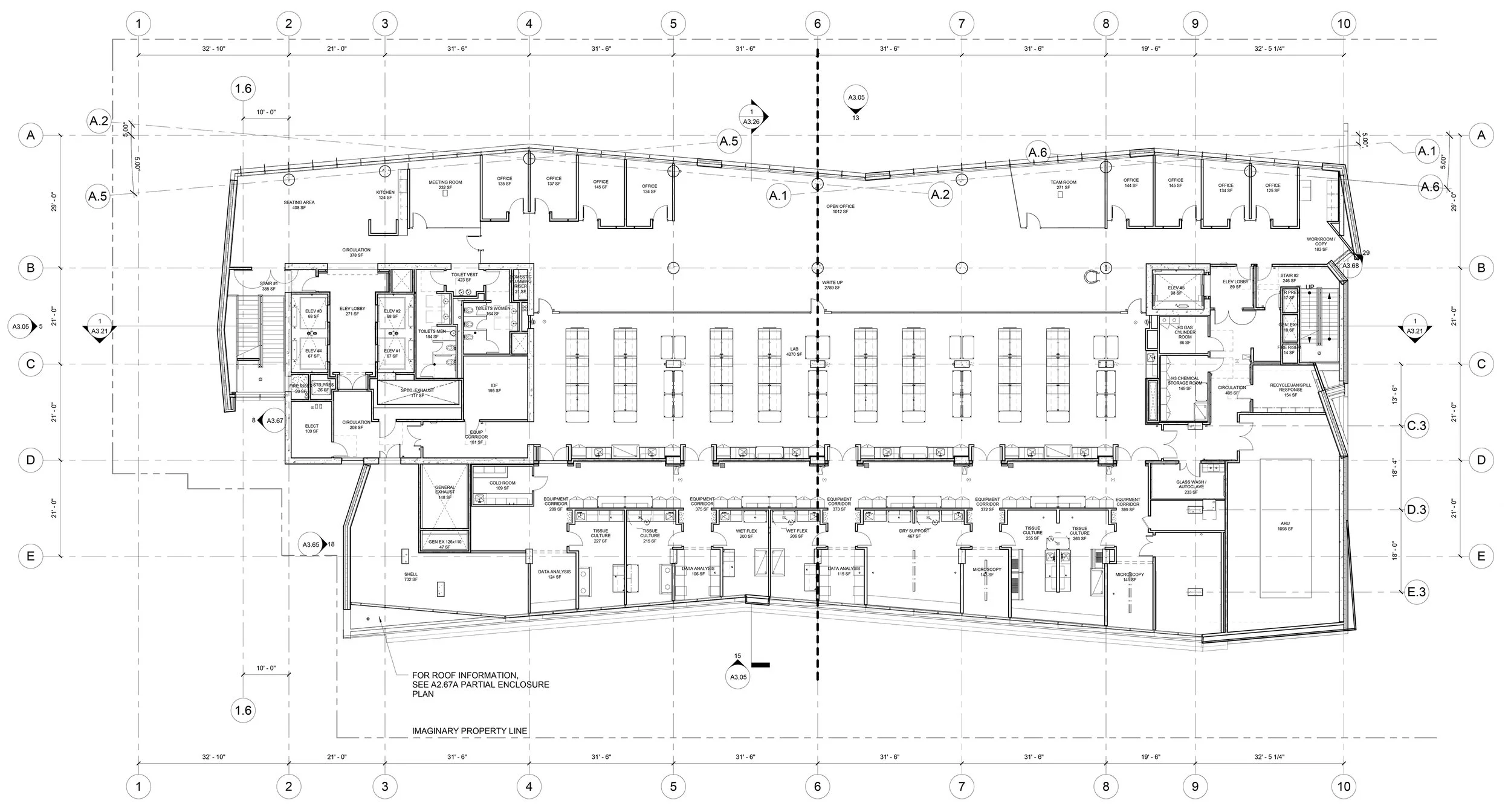

Typical Flex Lab Floor

Building layout is intended to offer flexibility to a variety of lab occupants, from PI-led research groups to individual researchers. Each lab floor accommodates different wet, dry, and flex lab configurations with minimal additional tenant-improvement work needed.

Each pair of lab floors has a shared social space for meetings and collaboration, including a small kitchen. The ground floor supports an academic conference center and the top floor holds an administrative suite.

I worked with CO’s lab planning team to develop floor plan layouts, program stacking, and building cores to support the high-rise building and meet requirements for fire and life safety.

Typical Flex Lab Floor Plan

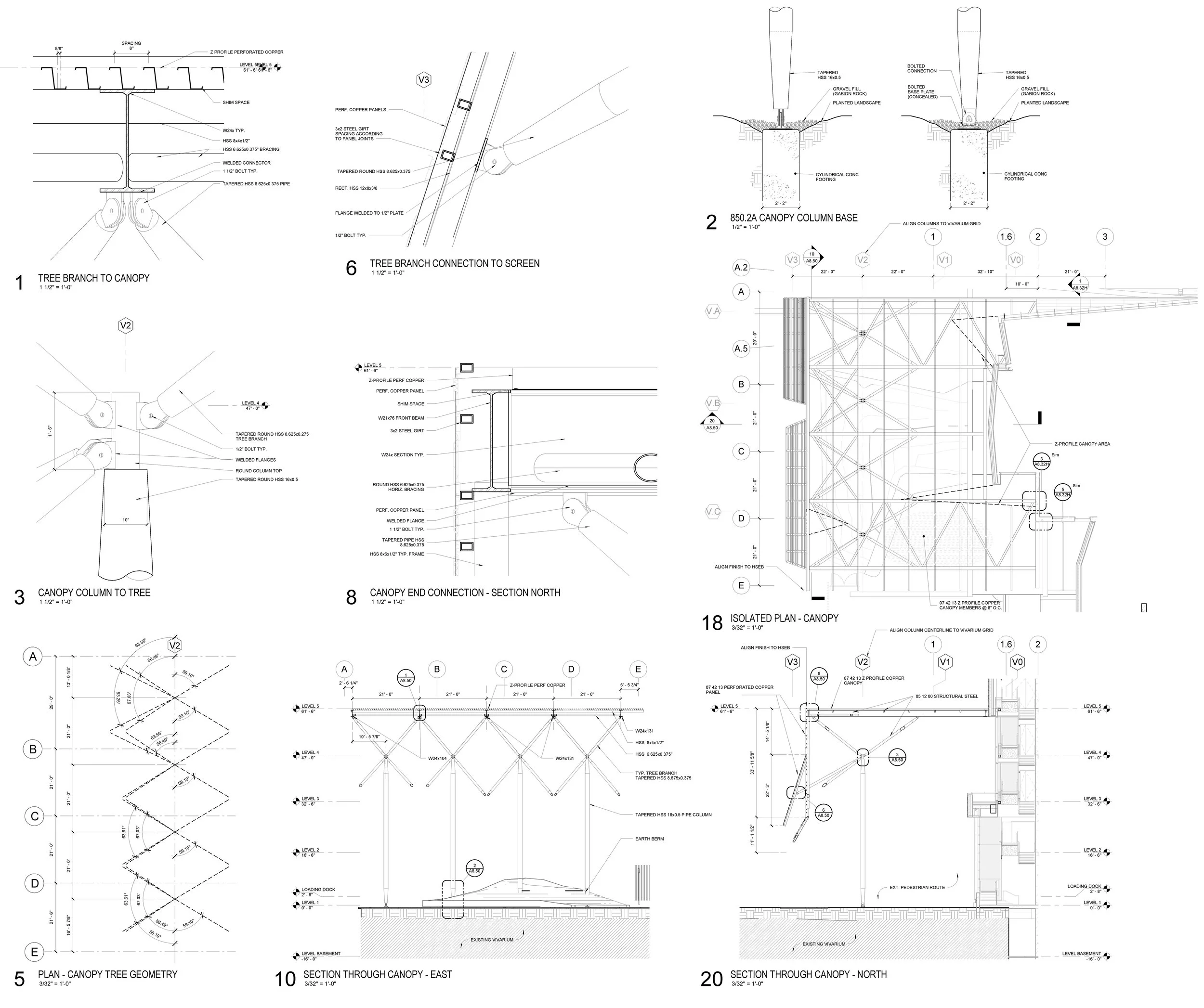

I developed the 3D and 2D CAD drawings for the 2-story ‘front porch’ canopy from a parametric model that enabled an iterative design approach and collaboration with the structural engineer for member sizing and layout.

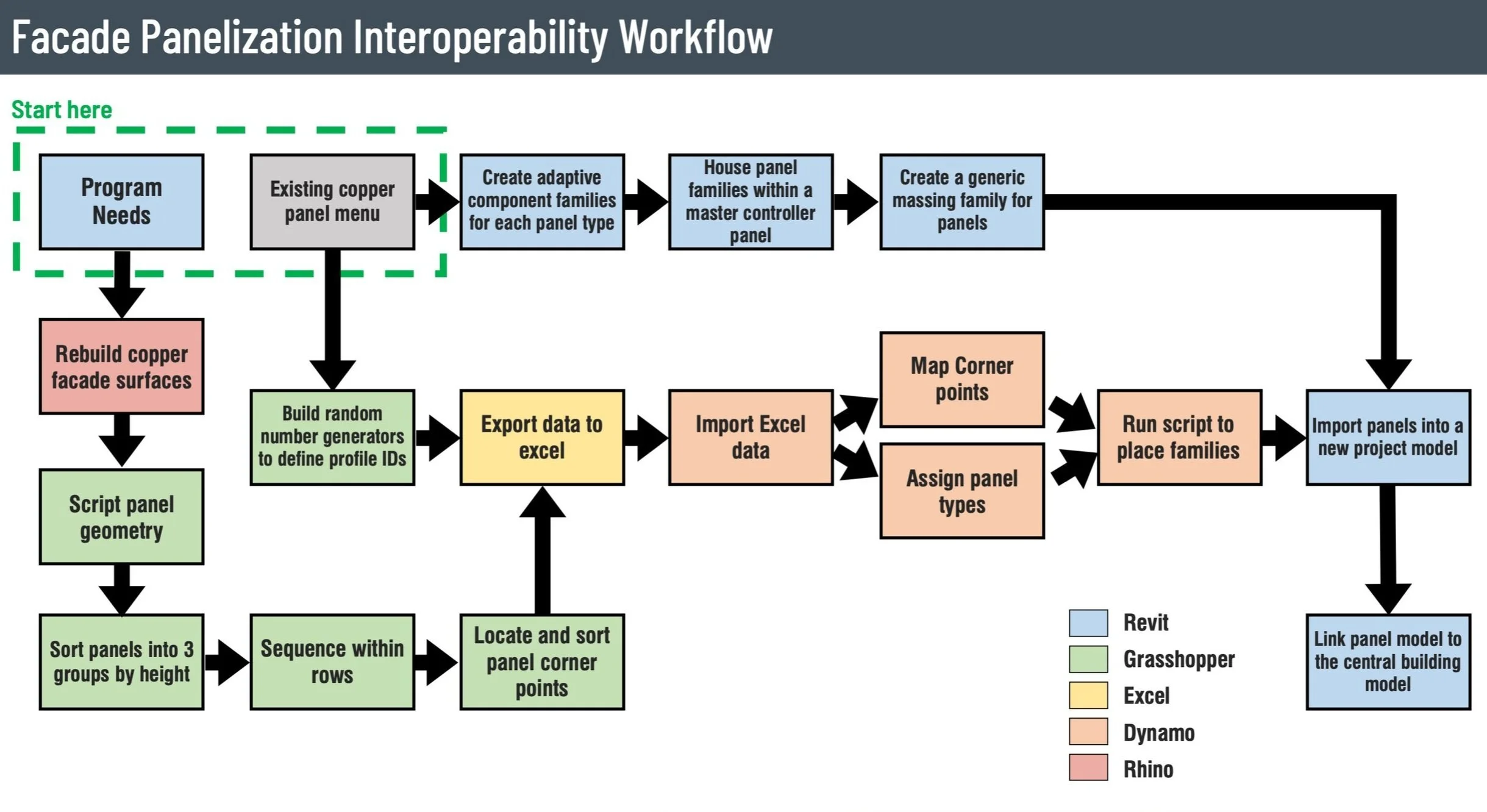

Facade Panelization

The copper-panel facade system, which had worked well on HSEB, needed to be adapted to the new building, which was larger and more complex geometrically. The HSEB facade was developed by painstakingly placing each panel manually in the 3D model, but we wanted to explore the ability of the visual scripting tools Grasshopper and Dynamo to automate the process. I developed the workflow and led a small team in this process, ultimately automating most steps from building out the 3D model for fabricator coordination to producing 2D CAD documentation for our contract drawings.

Set of panel types from HSEB used to panelize the new building

Progression from architectural model with generic walls to fully panelized facade surfaces

Panel family logic, supporting scripted sorting for continuous placement in rows

Parametric panel model placed into the facade coordination model

Parametric panel family adapted to each size, location, and type

Panelization workflow, spanning 5 different software platforms